Plastic Fillers Market Set for Strong Growth, Projected to Reach USD 24.6 Billion by 2035

The plastic fillers market size will grow from USD 14.0 Billion in 2025 to USD 24.6 Billion by 2035, fueled by demand for cost savings and high performance

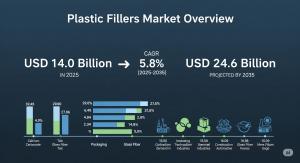

NEWARK, DE, UNITED STATES, August 8, 2025 /EINPresswire.com/ -- The Plastic Fillers Market is poised for sustained growth over the next decade, with its valuation expected to rise from USD 14.0 billion in 2025 to USD 24.6 billion by 2035, representing a CAGR of 5.8%. The market’s upward trajectory is being driven by industries’ ongoing focus on cost optimization, material performance enhancement, and environmental sustainability.

Market Outlook and Growth Drivers

Plastic fillers play a crucial role in reducing polymer usage while improving mechanical strength, thermal stability, and product durability. As manufacturers strive to balance engineering needs with environmental targets, fillers have become indispensable in sectors such as automotive, packaging, and construction. Evolving regulatory standards that encourage lightweight, recyclable, and high-performance materials are further reinforcing market demand.

The trend toward material circularity is also accelerating adoption, with both traditional mineral fillers and advanced functional additives being integrated into diverse plastic applications. Emerging economies are set to play a vital role, offering significant growth potential due to expanding manufacturing capabilities and rising demand for cost-effective material solutions.

Segmental Analysis

By Type: Calcium Carbonate Leading with 42.3% Share

Calcium carbonate is expected to hold the largest market share (42.3%) in 2025, making it the most widely used filler type. Its appeal lies in its high availability, low cost, and favorable mechanical properties when blended with various polymers. By improving rigidity, enhancing surface finish, and reducing shrinkage, calcium carbonate enables manufacturers to meet both economic and performance targets. Its compatibility with commodity and engineering plastics further strengthens its market position.

By Form: Nanofillers at the Forefront

In terms of form, nanofillers are projected to account for 35.7% of market revenue in 2025. Offering superior barrier strength, thermal stability, and reinforcement at lower loadings, nanofillers are gaining traction in advanced, precision-demanding applications. Innovations in nanotechnology and improved dispersion techniques have enhanced cost-effectiveness and consistency, making them the preferred choice for high-performance plastic products.

By Application: Automotive Dominates with 39.4% Share

The automotive industry is forecast to remain the largest application segment, capturing 39.4% of market revenue in 2025. Plastic fillers enable significant weight reduction without compromising strength, supporting fuel efficiency and compliance with strict emission regulations. Their ability to improve thermal stability, noise dampening, and aesthetic quality makes them essential in both conventional and electric vehicles.

Key Trends and Opportunities

Cost Reduction and Performance Enhancement

Fillers such as talc, glass fibers, and silica are increasingly utilized to reduce resin consumption while maintaining high stiffness, impact resistance, and dimensional accuracy. This dual advantage is critical for bulk applications like films, molded containers, and structural components where performance consistency is non-negotiable.

Rise of Biobased and Eco-Friendly Fillers

Sustainability initiatives are boosting demand for biobased fillers derived from agricultural waste such as rice husk powder and cellulose fiber. These not only enhance environmental credentials but also offer competitive performance, opening opportunities in packaging, furniture, and construction markets. Lightweight composite fillers, including hollow spheres and fiber blends, are also expanding possibilities in automotive and aerospace sectors.

Regional Insights

China: The Global Leader

China is projected to achieve the highest CAGR of 7.8%, supported by large-scale polymer production, strong domestic supply chains, and cost-efficient manufacturing. Widespread use of mineral fillers like calcium carbonate and talc helps lower production costs, particularly in high-volume applications such as packaging and electronics.

India: Fast-Growing Manufacturing Hub

India follows closely with a CAGR of 7.3%, driven by growth in packaging, automotive, and construction. Local industries prioritize cost reduction through filler-heavy compounds, with industrial clusters in Gujarat and Maharashtra integrating filler production into additive manufacturing ecosystems.

Germany: Precision and Performance

Germany’s 6.7% CAGR is fueled by demand for high-quality fillers in engineering plastics for automotive and electromechanical applications. The emphasis here is on certification, traceability, and mechanical performance, aligning with the country’s reputation for precision manufacturing.

United Kingdom: Circular Economy Focus

With a 5.5% CAGR, the UK market distinguishes itself through innovation in recycled-content materials and eco-friendly product development. Lightweight fillers are used to reduce packaging weight, while localized sourcing strategies support sustainability and supply chain resilience.

United States: High-Performance Applications

The US is set to grow at 4.9% CAGR, with emphasis on functional fillers that enhance flame retardancy, UV stability, and electrical conductivity. Regulatory requirements for food-contact and medical-grade materials are shaping the use of specialized, high-value fillers over bulk mineral alternatives.

Request Plastic Fillers Market Draft Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-22784

For more on their methodology and market coverage, visit! https://www.futuremarketinsights.com/about-us

Competitive Landscape

The plastic fillers market is moderately consolidated, with a mix of global leaders and specialized regional players. Imerys leads with a strong portfolio in mineral-based fillers, closely followed by Mineral Technologies Inc., Omya AG, and Huber Engineered Materials, which focus on high-performance and surface-treated solutions. BASF SE, Avient Corporation, and The Dow Chemical Company leverage their polymer expertise to integrate functional additives, while Hoffman Minerals and LKAB Group serve niche industrial needs. Competitive strategies center on R&D investment, cost optimization, and sustainable sourcing to address evolving customer and regulatory demands.

Related Reports:

Industry Analysis of Paper Bag in North America: https://www.futuremarketinsights.com/reports/industry-analysis-of-paper-bag-in-north-america

Industry Analysis of Lidding Film in the United States: https://www.futuremarketinsights.com/reports/industry-analysis-of-lidding-film-in-united-states

Industry Analysis of Stainless Steel IBC in the United States: https://www.futuremarketinsights.com/reports/industry-analysis-of-stainless-steel-ibc-in-united-states

Editor’s Note:

This release is based exclusively on verified and factual market content derived from industry analysis by Future Market Insights. No AI-generated statistics or speculative data have been introduced. This press release highlights significant shifts in the Plastic Fillers Market, which is experiencing a pivotal change driven by consumer demand for healthier, more transparent products.

Rahul Singh

Future Market Insights Inc.

+18455795705 ext.

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.