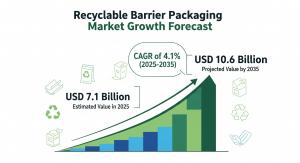

Recyclable Barrier Packaging Market to Hit USD 10.6 billion by 2035, Fueled by Eco Regulations and Material Innovation

Recyclable barrier packaging market will grow from USD 7.1 billion in 2025 to USD 10.6 billion by 2035 driven by sustainability laws, innovation & rising demand

NEWARK, DE, UNITED STATES, August 8, 2025 /EINPresswire.com/ -- The Recyclable Barrier Packaging Market, valued at USD 7.1 billion in 2025, is forecasted to grow to USD 10.6 billion by 2035, expanding at a 4.1% CAGR over the forecast period. This growth reflects the packaging industry’s rapid transition toward sustainability, with rising environmental regulations, consumer awareness, and material innovations driving adoption. Governments across the globe are imposing stricter recycling targets, and industries are responding by integrating recyclable solutions that meet both performance and environmental benchmarks. For manufacturers, recyclable barrier packaging is no longer optional—it is a business-critical investment that safeguards brand credibility while meeting compliance demands.

Material Innovation Driving Growth

The market’s momentum is anchored in material science advancements that enable high-performance barriers against moisture, oxygen, and contaminants without compromising recyclability. Innovations in mono-material plastics, recyclable paperboard, and barrier coatings have opened the door for sectors such as food and beverages, pharmaceuticals, and consumer goods to achieve extended shelf life, product integrity, and sustainability in a single package. As consumer preference increasingly tilts toward eco-conscious products, packaging solutions that combine functionality with environmental responsibility are becoming decisive factors in purchasing decisions.

Plastics Lead the Material Segment

Plastics remain at the forefront, projected to capture 38.5% of the market revenue in 2025. Their dominance is attributed to their adaptability, favorable barrier properties, and cost-effectiveness. Technological advances have improved the recyclability of plastic films, enabling them to preserve product quality while fitting into established recycling streams. In parallel, global investments in chemical and mechanical recycling infrastructure are strengthening the case for plastics in circular packaging models. For manufacturers, recyclable plastics offer the opportunity to align with sustainability goals while retaining performance and affordability—two critical factors in competitive markets.

Flexible Packaging Dominates Format Preferences

From a packaging format perspective, flexible packaging continues to lead with a projected 57.2% revenue share in 2025. Its lightweight nature, compact storage, and reduced carbon footprint in logistics make it a favorite among manufacturers looking to optimize transportation efficiency and minimize environmental impact. Flexible formats are also highly versatile, accommodating diverse product shapes and sizes while maintaining freshness. By integrating recyclable plastics and advanced barrier layers, manufacturers can meet both functional requirements and sustainability targets, ensuring flexible packaging’s continued market leadership.

Manufacturers Remain the Core End Users

On the demand side, manufacturers represent the largest end-user group, expected to contribute 46.8% of total market revenue in 2025. The drive toward recyclable barrier packaging among producers is fueled by a need to comply with evolving regulations, enhance brand reputation, and appeal to environmentally conscious consumers. In industries such as food, beverage, pharmaceuticals, and personal care, sustainable packaging has become a differentiator that reinforces trust, especially as buyers increasingly scrutinize corporate environmental commitments. Manufacturers adopting recyclable barrier formats are not only improving product safety and shelf life but also strengthening their market position.

Regional Growth Highlights

The geographic growth outlook highlights strong adoption in North America, Asia-Pacific, and Europe, with notable regional variations:

- China – 5.5% CAGR through 2035, driven by bans on non-recyclable plastics and rapid FMCG & e-commerce adoption.

- India – 5.1% CAGR, propelled by Extended Producer Responsibility (EPR) laws and demand from organized retail.

- Germany – 4.7% CAGR, supported by EU waste reduction directives and recycling innovation.

- United Kingdom – 3.9% CAGR, boosted by plastic tax incentives and retailer commitments.

- United States – 3.5% CAGR, with brand-led adoption of mono-material and high-barrier recyclable packaging.

Technological Innovations Creating Competitive Advantages

Innovation is creating new competitive advantages in the market. Developments in recyclable paperboard for dairy and beverage applications, mono-material PET jars with UV protection, and resin systems that enhance barrier performance while maintaining recyclability are expanding application possibilities. For example, the introduction of MXD6-based resins and BOPE-based flexible films with post-consumer recycled content shows that performance and circularity can coexist. Collaborations between resin suppliers, converters, and brand owners are accelerating these innovations, ensuring compatibility with existing recycling infrastructure and meeting circular economy targets.

Competitive Landscape

The competitive landscape is moderately consolidated, with leading players such as Amcor, Mondi, Berry Global, Tetra Pak, and Sealed Air setting the standard for recyclable barrier packaging performance. These companies are focusing on mono-material structures, advanced coating technologies, and recyclable laminates that replace traditional multi-layer systems. A standout example is Dow’s July 2025 launch of INNATE TF 220 Precision Packaging Resin for BOPE-based flexible films, incorporating post-consumer recycled content and enabling one of the first fully recyclable detergent packages in China through its partnership with Liby.

Request Recyclable Barrier Packaging Market Draft Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-22855

For more on their methodology and market coverage, visit! https://www.futuremarketinsights.com/about-us

Outlook for Manufacturers

Looking ahead, the recyclable barrier packaging market is poised to be a cornerstone of sustainable packaging strategies. Regulatory mandates will continue to push adoption, but equally important is the role of brand-driven sustainability commitments in shaping demand. Manufacturers that focus on circular material design, barrier performance optimization, and operational efficiency will secure a lasting competitive advantage. As packaging becomes an extension of a company’s environmental responsibility, recyclable barrier solutions will not only protect products—they will protect brand integrity and market relevance in a rapidly changing global economy.

Related Reports:

Horizontal Form Fill Seal (HFFS) Machines Market: https://www.futuremarketinsights.com/reports/horizontal-form-fill-seal-machines-market

Food Storage Bags Market: https://www.futuremarketinsights.com/reports/food-storage-bags-market

Case Packing Machines Market: https://www.futuremarketinsights.com/reports/case-packing-machines-market

Editor’s Note:

This release is based exclusively on verified and factual market content derived from industry analysis by Future Market Insights. No AI-generated statistics or speculative data have been introduced. This press release highlights significant shifts in the Recyclable Barrier Packaging Market, which is experiencing a pivotal change driven by consumer demand for healthier, more transparent products.

Rahul Singh

Future Market Insights Inc.

+18455795705 ext.

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.